Zirconium Carbide Nanoparticles: Properties, Synthesis, and Applications

Introduction

Zirconium carbide (ZrC) is a highly valuable ceramic material known for its exceptional hardness, high melting point, and chemical stability. When produced in nanoparticle form, zirconium carbide exhibits unique properties that enhance its performance in various high-tech applications. Due to its superior mechanical and thermal properties, ZrC nanoparticles are used in cutting-edge fields such as advanced ceramics, catalysis, and aerospace engineering.

Chemical Properties

- Composition: Zirconium carbide nanoparticles consist of zirconium and carbon in a 1:1 stoichiometric ratio. The material is characterized by its ability to form a solid solution with other carbides, which can be exploited to tailor its properties.

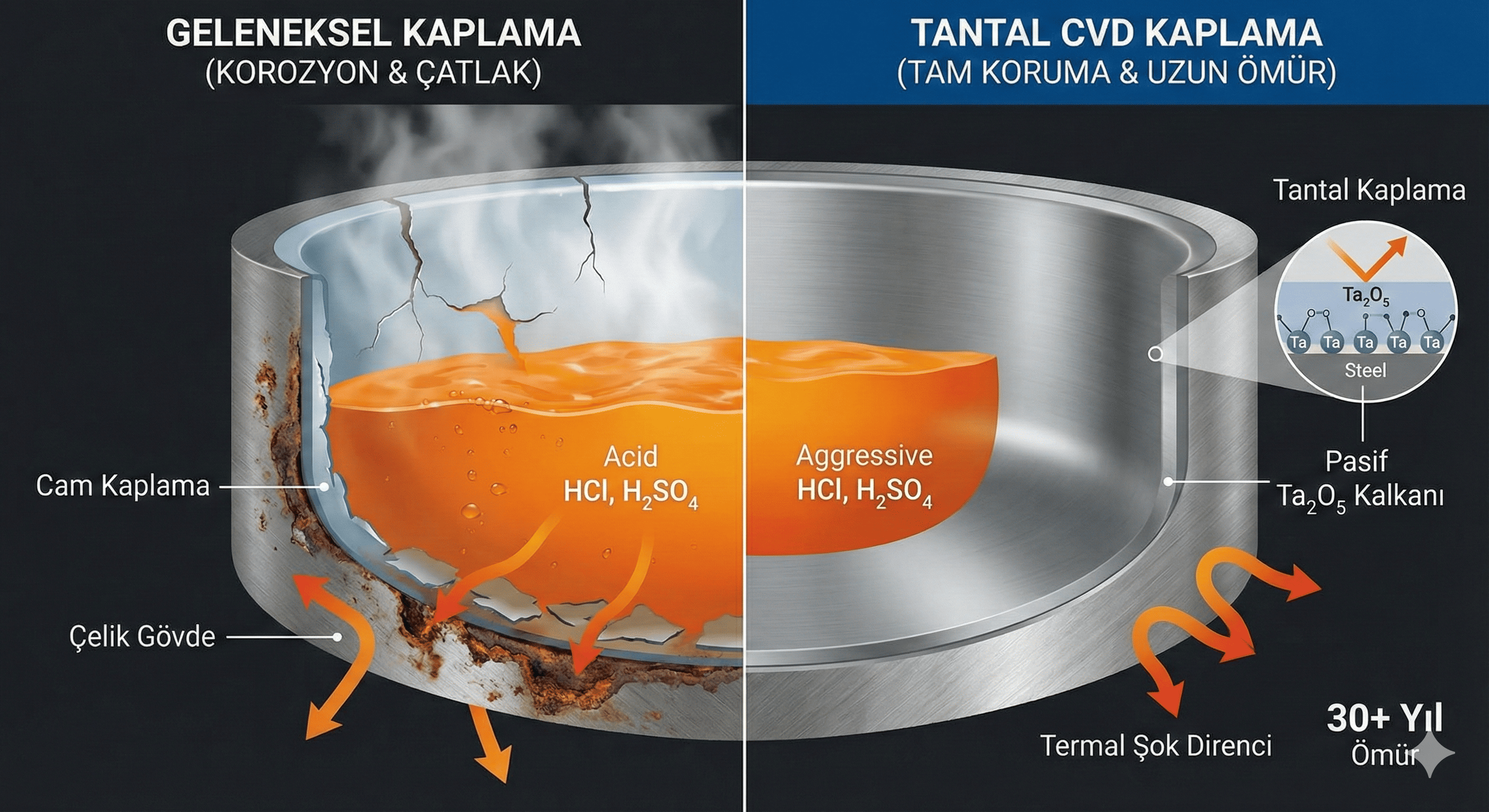

- Reactivity: ZrC is chemically stable and exhibits high resistance to oxidation and corrosion. It remains inert in most acidic and basic environments. However, it can react with strong oxidizers at high temperatures.

- Oxidation States: In ZrC, zirconium is in the +4 oxidation state, and carbon is in the -4 oxidation state. This oxidation state contributes to the compound’s stability and inertness.

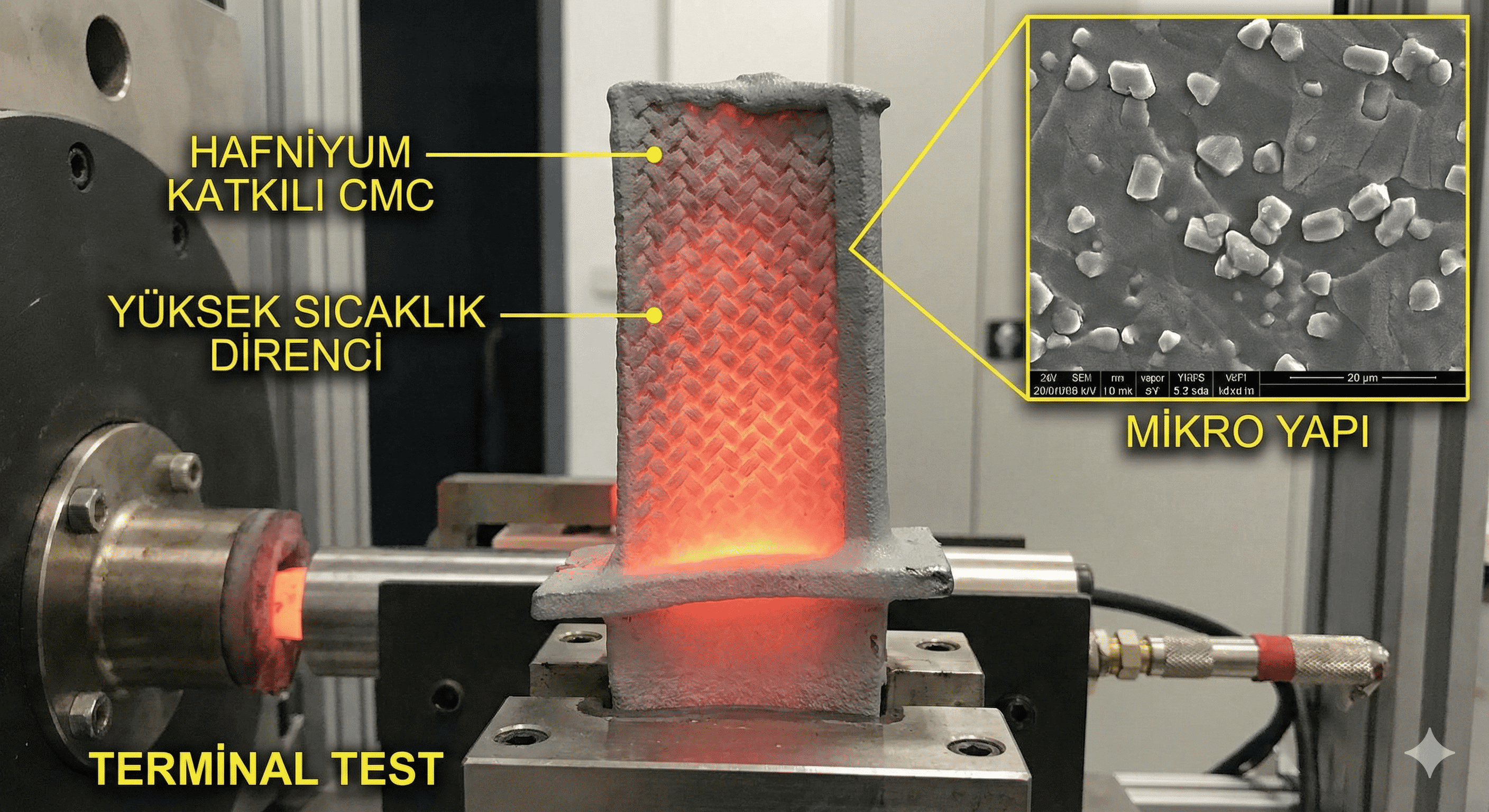

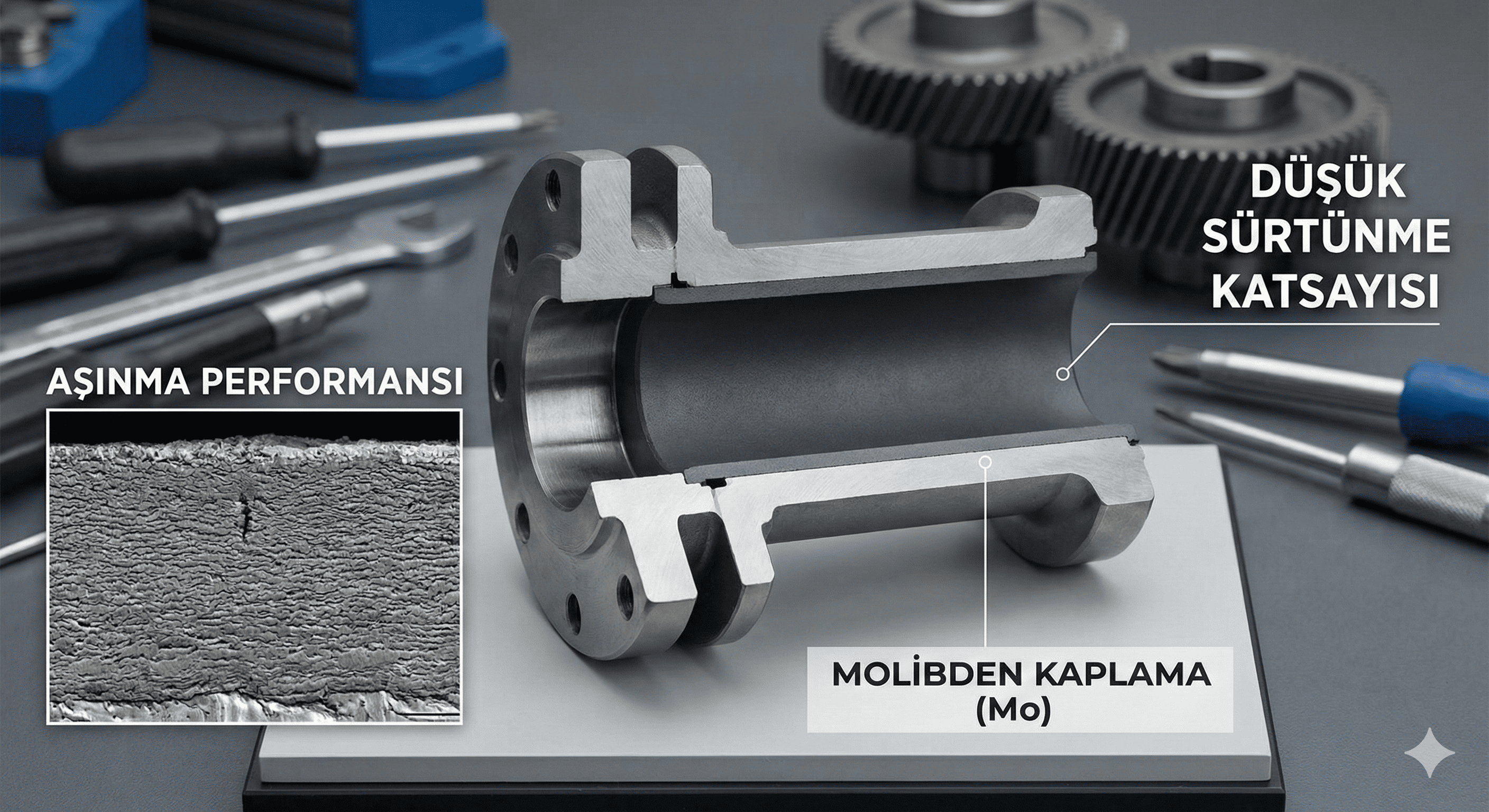

- Surface Chemistry: The surface properties of ZrC nanoparticles can be tailored through various modifications, such as coating or doping, to enhance properties like dispersion, reactivity, or adhesion in different applications.

Physical Properties

- Appearance: Zirconium carbide nanoparticles are typically black to dark gray powders. Their appearance can vary slightly depending on particle size and synthesis methods.

- Density: The density of ZrC is approximately 6.73 g/cm³. The density of nanoparticles can be influenced by factors such as particle size, porosity, and synthesis conditions.

- Melting Point: ZrC has a high melting point of around 3,550°C (6,422°F), making it suitable for applications requiring extreme thermal stability.

- Mechanical Properties:

- Hardness: ZrC nanoparticles are known for their exceptional hardness, which is higher than many other carbides and ceramics. This property makes them valuable for abrasive and cutting tool applications.

- Toughness: ZrC exhibits high toughness and resistance to wear, crack propagation, and thermal shock. These properties enhance its performance in demanding environments.

- Optical Properties: ZrC is generally opaque in the visible spectrum but has a high refractive index in the infrared region. Its optical properties are less commonly exploited compared to its mechanical and thermal attributes.

Synthesis Methods

- Chemical Vapor Deposition (CVD):

- Process: CVD is used to produce high-purity zirconium carbide nanoparticles by reacting zirconium and carbon precursors in a vapor phase at high temperatures. This method allows for precise control over particle size and morphology.

- Reaction: ZrCl4+CH4→ZrC+HCl+H2ZrCl_4 + CH_4 \rightarrow ZrC + HCl + H_2ZrCl4?+CH4?→ZrC+HCl+H2?

- Solution-Based Methods:

- Process: ZrC nanoparticles can be synthesized by combining zirconium salts and carbon sources in a liquid phase, followed by precipitation and calcination at high temperatures.

- Reaction: ZrOCl2+C→ZrC+CO+CO2ZrOCl_2 + C \rightarrow ZrC + CO + CO_2ZrOCl2?+C→ZrC+CO+CO2?

- Solid-State Reaction:

- Process: This method involves heating zirconium and carbon sources in solid form to produce ZrC nanoparticles. The reaction occurs at high temperatures and requires precise control to achieve the desired particle size and phase.

- Reaction: ZrO2+3C→ZrC+2COZrO_2 + 3C \rightarrow ZrC + 2COZrO2?+3C→ZrC+2CO

- Hydrothermal Synthesis:

- Process: ZrC nanoparticles can be synthesized through hydrothermal methods where zirconium and carbon precursors are reacted in aqueous solutions at high temperatures and pressures. Stabilizers or surfactants can be used to control particle size and distribution.

- Reaction: ZrO2+C (under hydrothermal conditions)→ZrCZrO_2 + C \text{ (under hydrothermal conditions)} \rightarrow ZrCZrO2?+C (under hydrothermal conditions)→ZrC

- Laser Ablation:

- Process: Laser ablation involves using a high-energy laser to vaporize zirconium and carbon targets in a controlled environment. The vaporized material condenses into nanoparticles upon cooling.

- Reaction: Zr+C (laser ablation)→ZrC (nanoparticles)Zr + C \text{ (laser ablation)} \rightarrow ZrC \text{ (nanoparticles)}Zr+C (laser ablation)→ZrC (nanoparticles)

Applications

- Advanced Ceramics: ZrC nanoparticles are used in the production of high-performance ceramics that require high hardness and thermal stability. Applications include cutting tools, wear-resistant coatings, and components in aerospace and defense industries.

- Catalysis: ZrC nanoparticles serve as catalysts or catalyst supports in various chemical reactions, including hydrogenation and hydrocarbon conversion. Their high thermal stability and catalytic properties make them suitable for industrial catalytic processes.

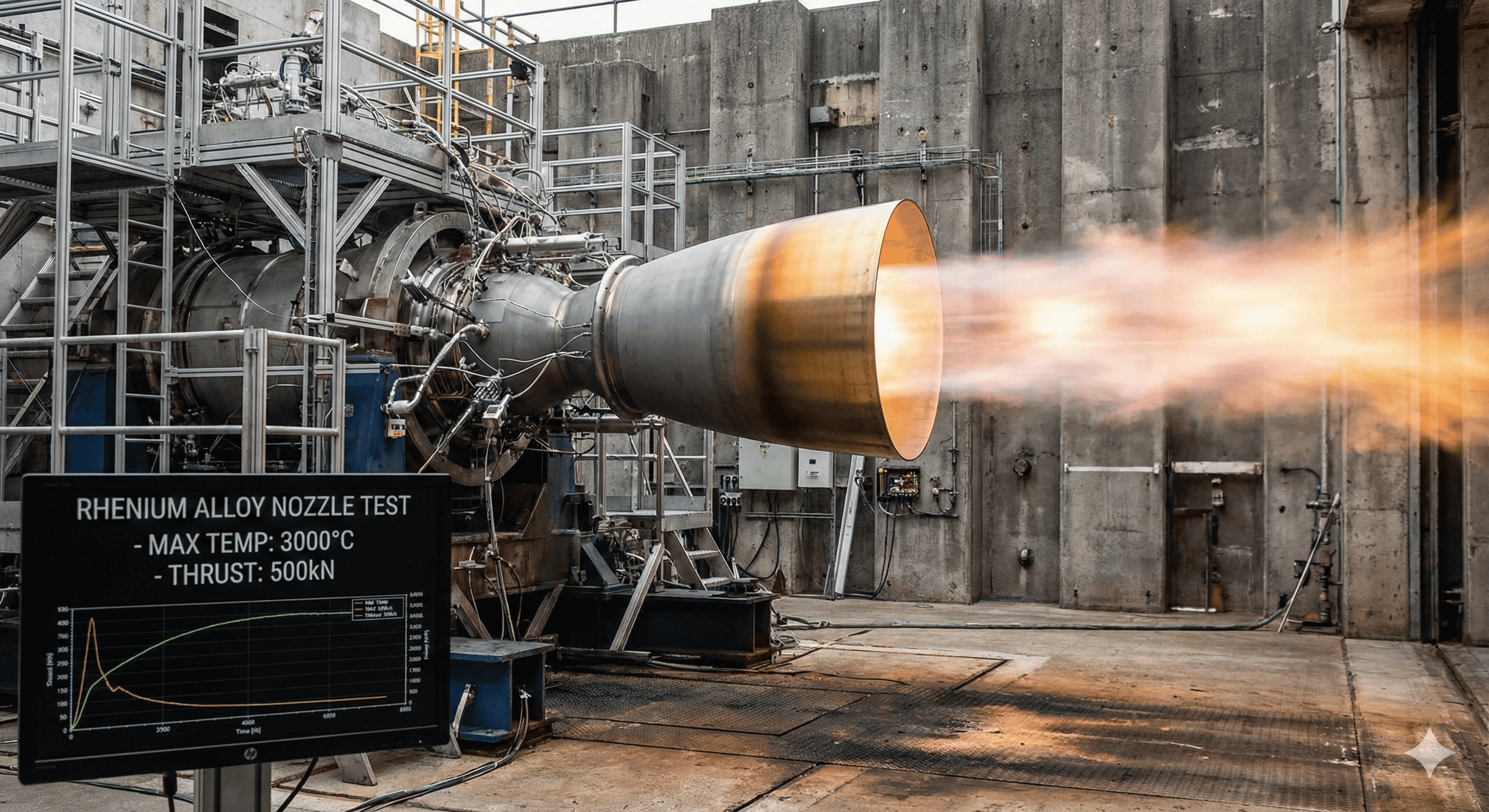

- Aerospace and Defense: Due to their high melting point and mechanical strength, ZrC nanoparticles are used in aerospace and defense applications, including thermal protection systems and high-temperature structural components.

- Electronics: ZrC nanoparticles are employed in electronic devices and systems that require high-temperature stability and durability. They are used in the manufacture of high-performance electronic components and sensors.

- Energy Storage: ZrC nanoparticles are explored for use in energy storage devices, such as batteries and supercapacitors, due to their high conductivity and stability under extreme conditions.

Safety and Handling

- Toxicity: Zirconium carbide is generally considered to have low toxicity. However, as with all fine powders, inhalation or ingestion should be avoided.

- Protective Measures: Use personal protective equipment (PPE) such as dust masks, safety goggles, and gloves when handling ZrC nanoparticles. Ensure good ventilation or work in a fume hood to minimize exposure.

- Storage: Store zirconium carbide nanoparticles in airtight containers to prevent contamination and moisture absorption. Keep them in a cool, dry place to maintain stability and prevent degradation.

Conclusion

Zirconium carbide nanoparticles are a crucial material in advanced technology due to their exceptional hardness, high melting point, and chemical stability. Their synthesis methods, properties, and applications span a wide range of fields, from advanced ceramics and catalysis to aerospace and electronics. Understanding the unique characteristics of ZrC nanoparticles helps optimize their use in various high-performance and high-temperature applications.

If you have any more questions or need further details, feel free to ask!