Silicon Carbide Nanoparticles: Properties, Synthesis, and Applications

Introduction

Silicon carbide nanoparticles (SiC NPs) are nanometer-sized particles composed of silicon and carbon. They are renowned for their exceptional hardness, thermal stability, and electrical properties, which make them valuable in a variety of high-tech and industrial applications. Silicon carbide is a compound of silicon and carbon, and when reduced to the nanoscale, it exhibits unique properties that differ significantly from bulk silicon carbide.

Chemical Properties

- Composition: Silicon carbide is composed of silicon (Si) and carbon (C) in a covalent bond. The general formula for silicon carbide is SiC, and it can exist in various polytypes, with the most common being 3C-SiC (cubic), 4H-SiC (hexagonal), and 6H-SiC (hexagonal).

- Reactivity: Silicon carbide is chemically resistant and does not easily react with acids or bases. However, it can react with strong oxidizers at high temperatures, forming silicon dioxide (SiO²) and carbon dioxide (CO²).

- Surface Chemistry: The surface of silicon carbide nanoparticles can be functionalized with various chemical groups to enhance their properties or enable specific interactions with other materials.

Physical Properties

- Size and Shape: Silicon carbide nanoparticles typically range from 1 to 100 nanometers in diameter. They can have various shapes, including spherical, rod-like, or irregular, depending on the synthesis method.

- Hardness: SiC NPs are extremely hard and have a hardness of around 9 to 9.5 on the Mohs scale, which makes them one of the hardest known materials. This property is useful for applications requiring abrasion resistance.

- Thermal Stability: Silicon carbide nanoparticles have high thermal stability, with a melting point of approximately 2,700°C (4,892°F). They retain their structural integrity at high temperatures, making them suitable for high-temperature applications.

- Electrical Properties: SiC NPs exhibit semiconductor properties and can be either n-type or p-type semiconductors. They have high breakdown voltage and thermal conductivity, which are advantageous for electronic and power device applications.

- Optical Properties: Silicon carbide nanoparticles can have photoluminescence properties, which are useful for optical applications. The optical properties can be tuned by altering the particle size and polytype.

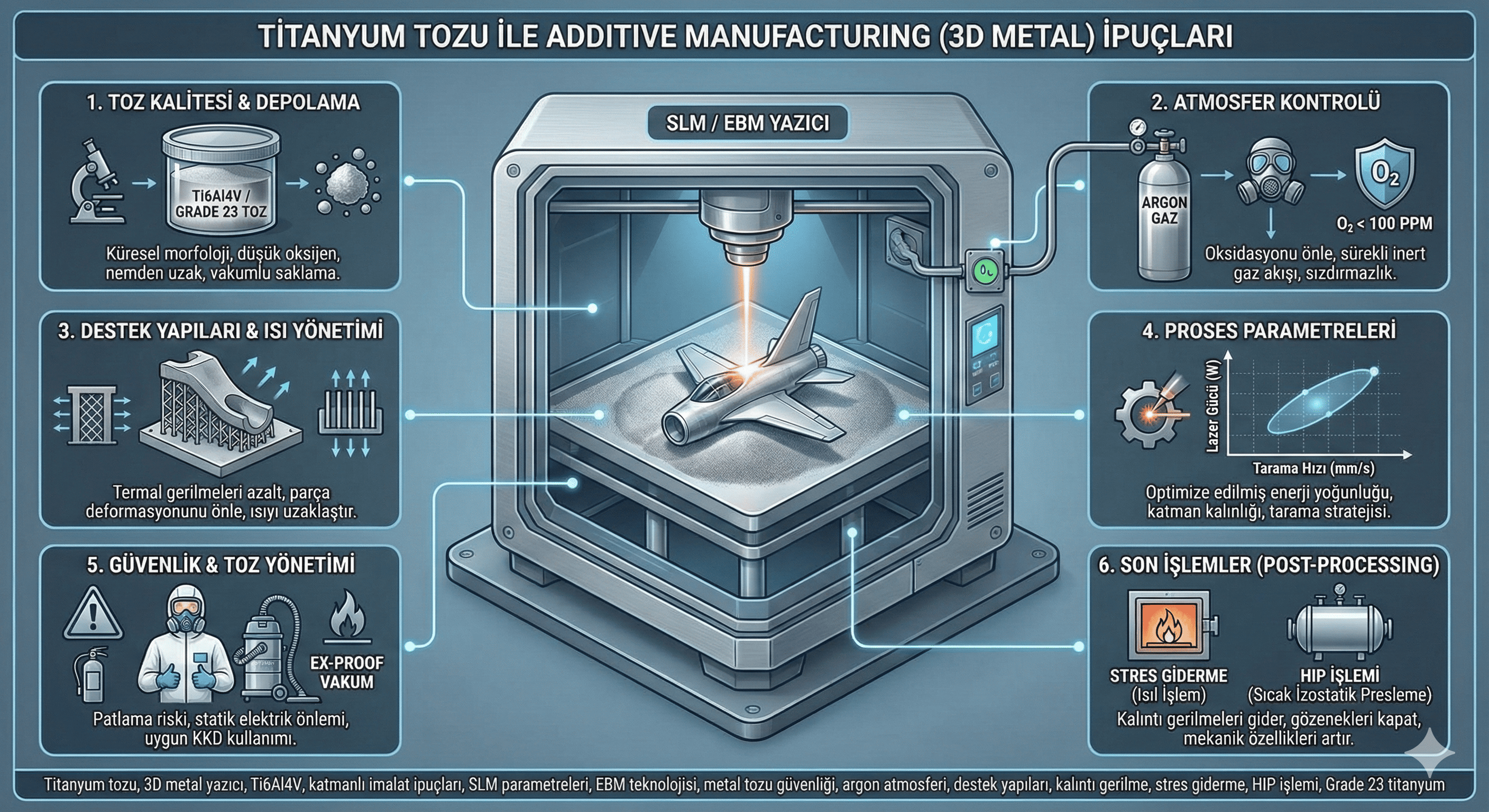

Synthesis Methods

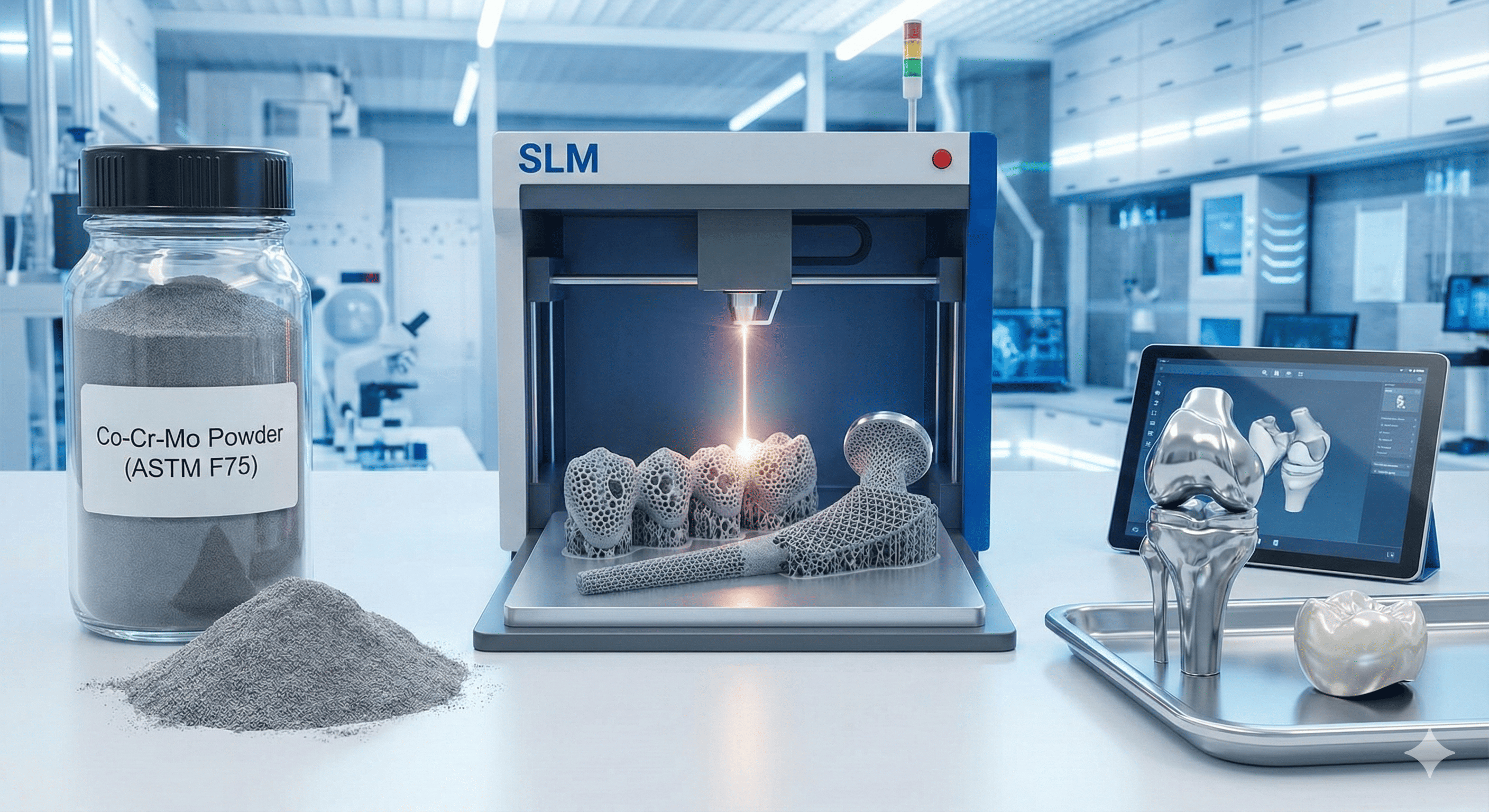

- Chemical Vapor Deposition (CVD): In CVD, silicon and carbon precursors are introduced into a reaction chamber where they react at high temperatures to form silicon carbide nanoparticles. This method allows for precise control over particle size and purity.

- Laser Ablation: Silicon carbide nanoparticles can be produced by ablating a silicon carbide target with a high-energy laser. The process generates nanoparticles as the material vaporizes and condenses.

- Sol-Gel Method: The sol-gel process involves the hydrolysis and condensation of silicon and carbon precursors to form a gel, which is then converted into silicon carbide nanoparticles through high-temperature treatment.

- Chemical Reduction: Silicon carbide nanoparticles can be synthesized by reducing silicon-containing compounds with carbon in a high-temperature furnace. This method produces SiC NPs with controlled size and morphology.

- Hydrothermal Synthesis: This method involves the reaction of silicon and carbon precursors in a high-temperature aqueous solution. Hydrothermal conditions facilitate the formation of silicon carbide nanoparticles with specific characteristics.

Applications

- Electronics: Silicon carbide nanoparticles are used in power electronic devices, such as Schottky diodes and MOSFETs, due to their high thermal conductivity and breakdown voltage. They are also used in high-frequency and high-power electronic applications.

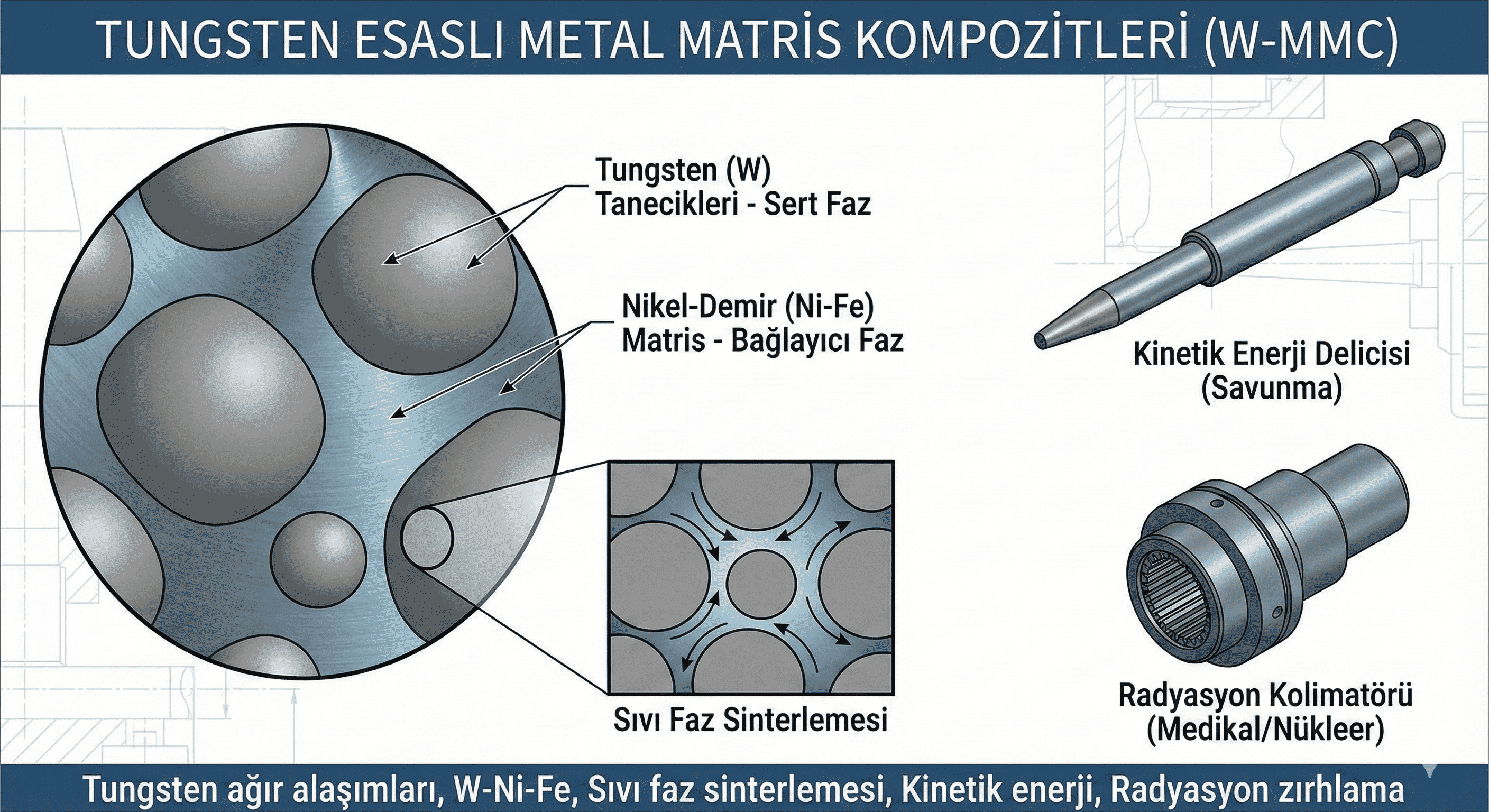

- Materials Science: SiC NPs are used as reinforcing agents in composites to improve mechanical properties such as hardness and wear resistance. They are also used in the production of advanced ceramics.

- Cutting Tools: Due to their exceptional hardness, silicon carbide nanoparticles are used in cutting tools, abrasives, and grinding materials. They enhance the durability and performance of these tools.

- Catalysis: SiC NPs serve as catalysts or supports in various chemical reactions. Their high surface area and stability make them effective in catalytic processes, including environmental catalysis and chemical synthesis.

- Energy Storage: Silicon carbide nanoparticles are explored for use in energy storage devices, such as batteries and supercapacitors, due to their high thermal stability and electrical conductivity.

Safety and Handling

- Toxicity: Silicon carbide nanoparticles are generally considered to have low toxicity. However, inhalation of fine dust can cause respiratory issues, and appropriate precautions should be taken to avoid exposure.

- Protective Measures: Use personal protective equipment (PPE), including dust masks, safety goggles, and gloves, when handling silicon carbide nanoparticles. Work in a well-ventilated area or fume hood to minimize inhalation risks.

- Storage: Store silicon carbide nanoparticles in airtight containers to prevent contamination and moisture absorption. Keep them in a cool, dry place to maintain stability.

Conclusion

Silicon carbide nanoparticles are a highly valuable material with a wide range of applications across electronics, materials science, cutting tools, catalysis, and energy storage. Their unique properties, including hardness, thermal stability, and electrical conductivity, make them essential for advanced technologies and industrial processes. Understanding their synthesis, properties, and safety considerations is crucial for effectively utilizing silicon carbide nanoparticles in various applications.

If you have more questions or need additional information, feel free to ask!