Silicon Carbide Nanofibers: Properties, Synthesis, and Applications

Introduction

Silicon carbide nanofibers (SiC NFs) are one-dimensional nanostructures composed of silicon carbide. They combine the unique properties of silicon carbide with the enhanced characteristics provided by their nanofiber morphology. Silicon carbide nanofibers are known for their exceptional mechanical strength, thermal stability, and electrical properties, making them highly valuable in advanced materials science and technology.

Chemical Properties

- Composition: Silicon carbide nanofibers are made of silicon and carbon, with the general formula SiC. The silicon and carbon atoms are covalently bonded in a crystal lattice, forming a robust structure.

- Reactivity: SiC nanofibers are chemically stable and exhibit high resistance to oxidation and corrosion at elevated temperatures. They do not easily react with acids or bases but can react with strong oxidizing agents at high temperatures.

- Surface Chemistry: The surface of silicon carbide nanofibers can be modified to improve their interactions with other materials or to enhance their properties. Surface treatments can include oxidation, coating with other materials, or functionalization with organic molecules.

Physical Properties

- Size and Shape: Silicon carbide nanofibers typically have diameters ranging from 50 nanometers to several micrometers and lengths extending to several millimeters. Their high aspect ratio (length to diameter) contributes to their unique properties.

- Mechanical Properties: SiC nanofibers are known for their exceptional mechanical strength and stiffness. They have high tensile strength, high Young’s modulus, and excellent resistance to deformation, making them suitable for reinforcing materials.

- Thermal Properties: Silicon carbide nanofibers exhibit excellent thermal stability, with a high melting point around 2,700°C (4,892°F). They maintain their structural integrity at high temperatures and have low thermal expansion coefficients.

- Electrical Properties: SiC nanofibers possess good electrical conductivity and are used in electronic applications where high breakdown voltage and thermal conductivity are required. They are also used as conductive fillers in composite materials.

- Optical Properties: The optical properties of silicon carbide nanofibers can vary based on their size and surface characteristics. They can exhibit unique light absorption and scattering properties, useful in optical and sensing applications.

Synthesis Methods

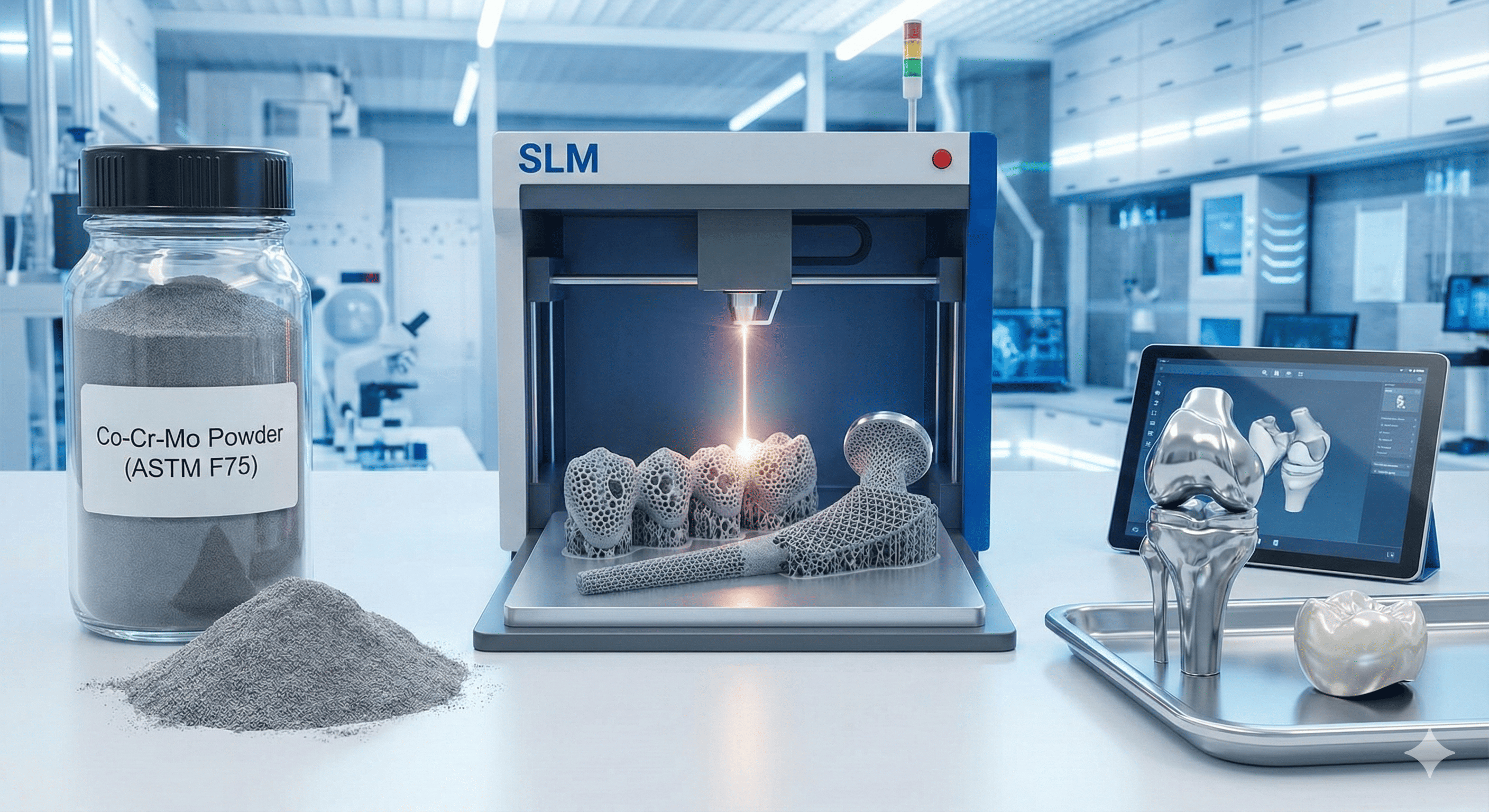

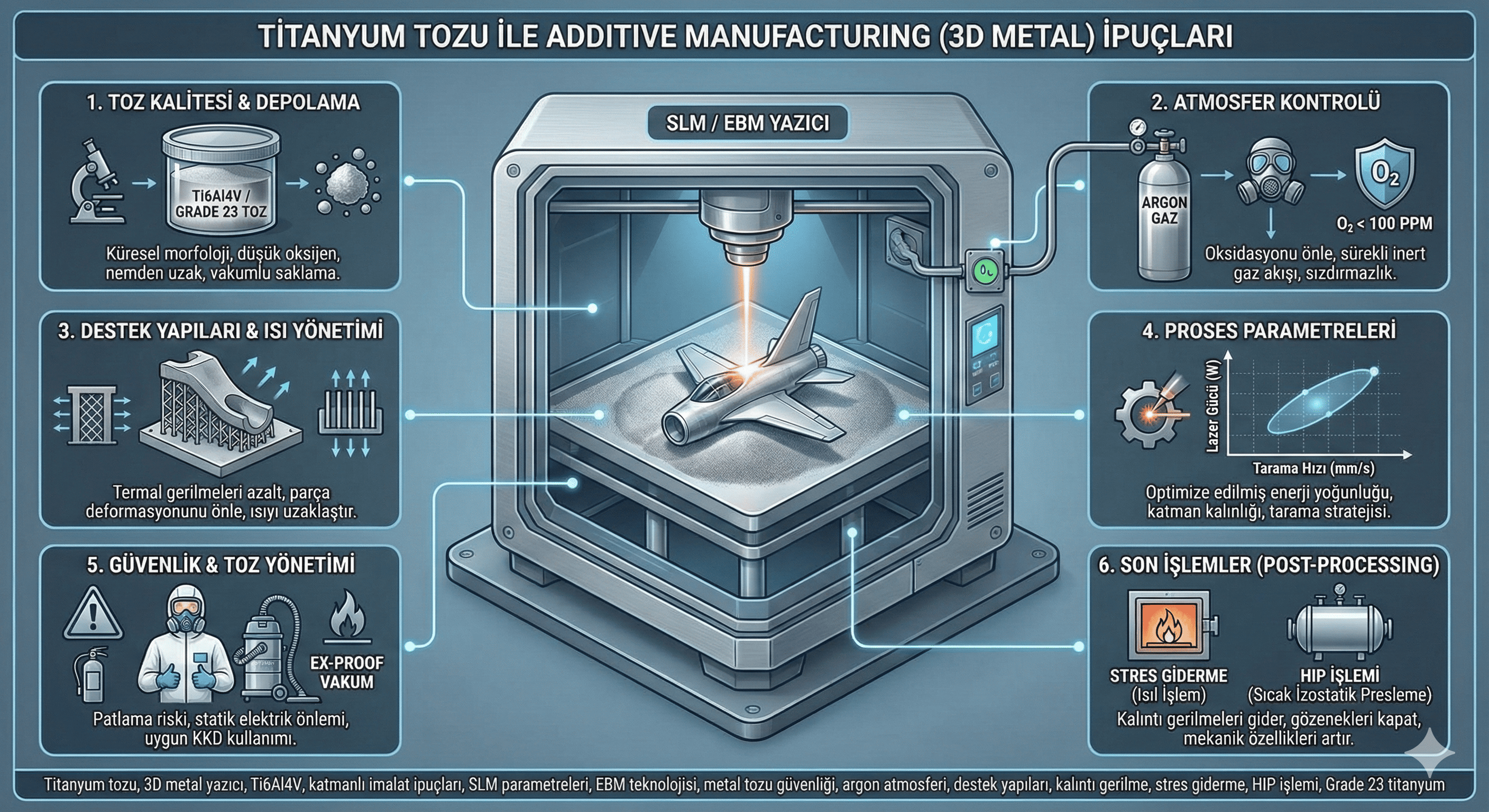

- Chemical Vapor Deposition (CVD): CVD is a common method for synthesizing silicon carbide nanofibers. Silicon and carbon precursors are introduced into a reaction chamber, where they decompose at high temperatures to form SiC nanofibers. The process allows for precise control over the fiber morphology and quality.

- Electrospinning: In electrospinning, a polymer solution containing silicon carbide precursors is subjected to a high-voltage electric field, resulting in the formation of nanofibers. The fibers are then converted to silicon carbide through a pyrolysis process.

- Sol-Gel Method: The sol-gel method involves the formation of a silicon carbide gel from silicon and carbon precursors. This gel is then transformed into nanofibers through heat treatment or chemical reduction.

- Template-Assisted Methods: Silicon carbide nanofibers can be synthesized using template-assisted methods, where a porous template is used to guide the formation of nanofibers. After the synthesis, the template is removed to leave behind the nanofibers.

- Hydrothermal Synthesis: This method involves the reaction of silicon and carbon precursors in a high-temperature aqueous solution under pressure. It can produce silicon carbide nanofibers with specific sizes and properties.

Applications

- Reinforcement in Composites: Due to their high strength and stiffness, silicon carbide nanofibers are used as reinforcement in various composite materials, including polymers, ceramics, and metals. They enhance the mechanical properties and durability of these materials.

- Electronics and Power Devices: SiC nanofibers are used in electronic devices such as high-temperature transistors and power devices. Their high thermal conductivity and electrical properties make them ideal for these applications.

- Thermal Protection Materials: The excellent thermal stability of silicon carbide nanofibers makes them suitable for use in thermal protection materials and coatings. They are used in high-temperature environments to protect surfaces from extreme heat.

- Sensors and Catalysts: Silicon carbide nanofibers are employed in sensors and catalytic applications due to their high surface area and stability. They can be used in gas sensors, chemical sensors, and as catalyst supports in various chemical reactions.

- Energy Storage: SiC nanofibers are explored for use in energy storage devices such as batteries and supercapacitors. Their high conductivity and stability contribute to the performance of these devices.

Safety and Handling

- Toxicity: Silicon carbide nanofibers are generally considered to have low toxicity. However, fine particulate matter can pose respiratory risks if inhaled. Safety data sheets and toxicological studies should be reviewed for specific handling guidelines.

- Protective Measures: When handling silicon carbide nanofibers, use appropriate personal protective equipment (PPE), including dust masks, safety goggles, and gloves. Work in a well-ventilated area or fume hood to minimize exposure to airborne particles.

- Storage: Store silicon carbide nanofibers in sealed, airtight containers to prevent contamination and moisture absorption. Keep them in a cool, dry place to maintain their stability and prevent degradation.

Conclusion

Silicon carbide nanofibers are advanced nanomaterials with exceptional mechanical, thermal, and electrical properties. Their unique characteristics make them suitable for a wide range of applications in materials science, electronics, thermal protection, and energy storage. Understanding their synthesis, properties, and safety considerations is essential for effectively utilizing silicon carbide nanofibers in various technological and industrial applications.

If you have more questions or need additional details, feel free to ask!